“No matter what, the team doesn’t do ugly anymore.”

After working closely with sixfoot-four in the past years, that is what happened to the R&D team at Repak, a machine engineering company in the Netherlands.

Read in this interview what engineers Lars van der Wal and Pim de Rue think of design, how their view changed over time and what they got out of it at the end.

One of my biggest project up till now started right in the middle of the second lockdown. I was asked to help a team of R&D engineers to develop their next generation machine as an external design consultant.

“I already met Franziska during a sprint we did earlier. I’ll never forget the millions of post-its everywhere” says Pim with a broad smile on his face, “and then corona happened.”

creating together at a distance

In the beginning, everyone had to work from home. We made do with a fully digital kick-off and continued to work together creatively at a distance. Rather successfully, as one engineer puts it:

Lars: “The way we still meet online now, it feels almost as if we’re sitting next to each other. I’m totally hooked.

Pim: “It was new for us back then, but of course we had to make it work in no time as well.”

From the start, we used large online whiteboards on Miro in a surprisingly smooth and efficient manner:

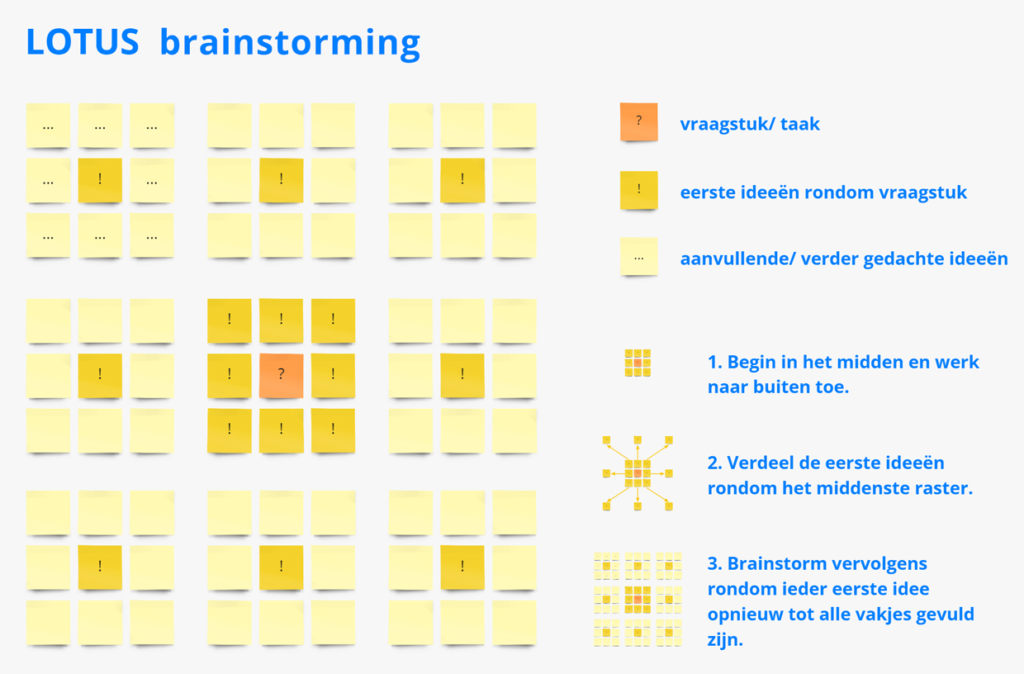

Lars: “We tackled this project in a very innovative way. Techniques such as the lotus flower, they just work. It’s a simple tool to generate lots of great ideas in a very short time. And they’re immediately clustered as well.

Pim: “The whole project is now a giant well of information. We brainstormed and associated freely as if there’s no tomorrow, and eventually narrowed down on a thin line for which we now work out all the details. It’s super valuable to be able to always look back in time.”

Lars: “An interactive online session can be quite embarrassing for some. However, the way we did, it is a great way to get even the toughest engineer creative and excited. A lotus flower works, visual brainstorming works, using a Miro bord just works.”

creating value for both the project and the team

How was working with 6’4” like?

Lars: “Our development process used to be very dependent on individual people. The big advantage now is that we lost our old blinkers.”

Pim: “We were accustomed to thinking along a certain path, based on how things were done in the past and your experience from back then. Now we got a different perspective. And that’s been super valuable. Also, I think because of looking at things differently, we work better together as a team.

You come from a very different background and you taught us to look at our machines in a different way. Things like ‘using a soft line’ or ‘creating a roller coaster for the eye’ suddenly become important and make sense.”

Lars: “What I really liked and what also proved very effective is how you take charge as an external. Within a certain framework, we’re also asked to contribute of course. If we hadn’t gone with an external, one of us would have had to fill that role. Someone without that kind of experience. You on the other hand know how to handle us as a team.

Pim: “Imagine if we had done this project without you. Without anybody to guide us and to tell us at certain moments: let’s take these steps, we’re focusing too much on that, let’s park this for now. When you don’t have that leadership, you end up drowning in details.”

Lars: “No one questions our technical expertise, but this is a design project as well. It needs to look different, more modern. I don’t think that we would have managed so well without someone external who’s got that experience, looks with a fresh set of eyes, and takes charge as well.”

Who would you recommend this process to?

Lars: “For engineering, this method works wonders. If you got a machine factory where people work with blinkers on, veterans and newcomers, a diverse team so to speak, then this approach works really well and will lead to something everybody can be proud of.”

What surprised you most during this project?

Lars: “At one point in time, the new line of our competitor was introduced and of course we gave it our own rating as a team. What I thought was funny was how I immediately started joking over how their machine looked, and not so much what their new features were like.

I know that their engineers put a lot of energy into their machine, but in the end their result felt not impressive at all. We probably would have come up with something similar if we hadn’t had the support from 6’4” along the way.

A straightforward machine where everything is purely focused on practical issues, without any regard to composition and visual rhythm. That’s when I first saw the difference between letting engineers have their way and getting external support from someone who knows this kind of stuff.”

What’s the value in having ‘visual rhythm’?

Lars: “It’s difficult to describe. It’s about balance and ease, I guess. I’m not good at labeling such things. But I immediately saw the straightforward noise and imbalance in the new model of our competitor. Parting lines that do not match, that sort of thing.”

Pim: “Had we done this project on our own, we wouldn’t have come up with something unique either.”

Lars: “I’m really curious how our new machine will be received by the public.”